This is the stage where the "skeleton" of the display cabinet is built. In this workshop, we use professional cutting, bending, welding, and grinding equipment to precisely process metals like steel and aluminum, creating the cabinet's frame, support structures, rails, and various custom metal components. The core of this step is to ensure all metal parts are dimensionally accurate, structurally solid, and have smooth surfaces, laying a solid foundation for the stability and durability of the entire display cabinet.

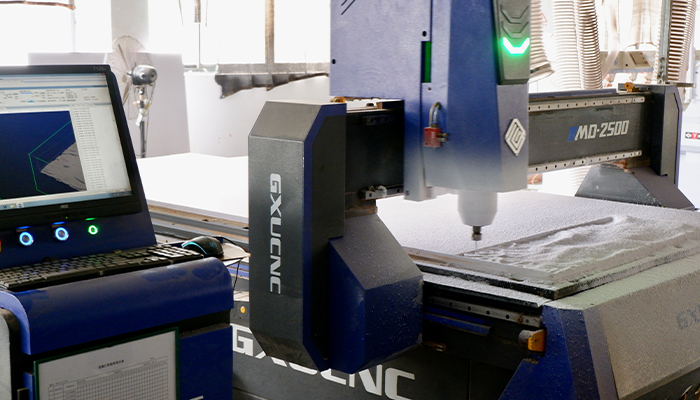

The wood workshop is responsible for shaping the "skin and body" of the display cabinet. Skilled carpenters use panel saws, CNC machines, edge banders, and other equipment to cut, mill, shape, and edge various board materials (such as fireproof board, solid wood, MDF, etc.) to produce the main wooden components like the cabinet body, shelves, drawers, and doors. This step focuses on the precise processing of materials and attention to detail, ensuring all wooden parts meet the highest standards for shape, size, and seams as required by the design.

The paint workshop is the key (link) where the final color and texture are (bestowed upon) the display cabinet. Here, pre-treated components (e.g., sanded, cleaned) receive a high-quality finish in the specified color through processes like spraying or baking. The process typically involves primer, topcoat, and multiple sanding stages to ensure a full paint film, even color, high-end texture, and resistance to wear and scratches. Whether it's high-gloss, matte, or special effects, it is achieved in this step, significantly enhancing the cabinet's aesthetics and commercial value.

The glass workshop specializes in handling the "transparent windows" of the display cabinet. Technicians precisely cut, edge (straight, round, beveled), drill, and temper flat glass according to design drawings to produce countertop glass, shelf glass, door glass, etc. This step requires extremely high standards of safety, precision, and smoothness, ensuring each glass component fits perfectly and provides a clear, transparent visual effect for safely and reliably displaying merchandise.

The acrylic workshop is responsible for creating various complex-shaped transparent or colored plastic components. Utilizing the excellent thermoplasticity of acrylic sheets, processes like cutting, engraving, heat bending, polishing, and bonding are used to create components such as lightboxes, display stands, brand logos, and specially shaped panels. The core advantage of this step is the ability to realize rich creative designs, producing lightweight, light-transmitting, aesthetically pleasing, and weather-resistant parts that add modernity and visual appeal to the display cabinet.

The lighting workshop is the "finishing touch" that creates the atmosphere and highlights the merchandise. Here, specialists select, cut, wire, and test lighting components like LED strips, spotlights, and light bars based on optical design. They create standard lighting modules and ensure all electrical connections are safe and reliable. The goal of this step is to provide the most suitable color temperature, brightness, and lighting angles to Cof the display.

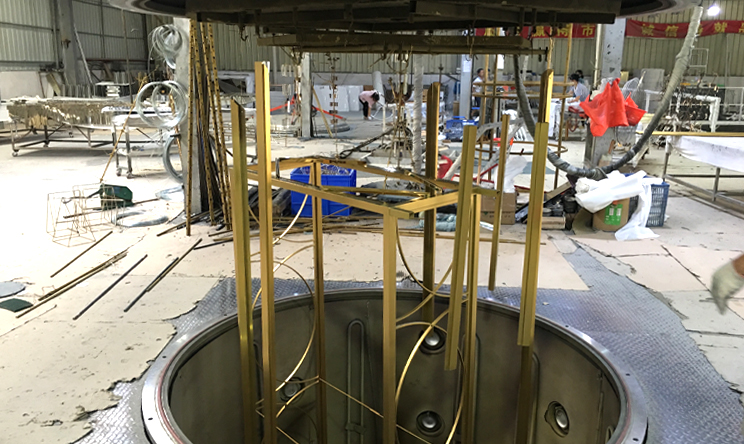

This step aims to enhance the corrosion resistance of metal parts and give them a specific decorative appearance. Depending on design requirements, various processes may be used, such as electroplating (chrome, titanium), spraying (powder coating, painting), brushing, anti-oxidation, or etching. These treatments not only effectively prevent rust and wear but can also produce various high-end finishes like stainless steel original color, champagne gold, black steel, or antique bronze, ensuring the metal components achieve optimal functionality and aesthetics.

Assembly is the final stage where all individually processed parts are integrated into the finished product. Experienced assemblers in a clean workshop carefully put together all components—metal structures, wooden cabinets, glass, acrylic parts, lighting systems—according to strict instructions, followed by testing and adjustment. This step ensures every screw, every panel, and every light is in place, fitting together perfectly. The result is a sturdy, stable, fully functional, and aesthetically pleasing high-quality display cabinet, ready for delivery.